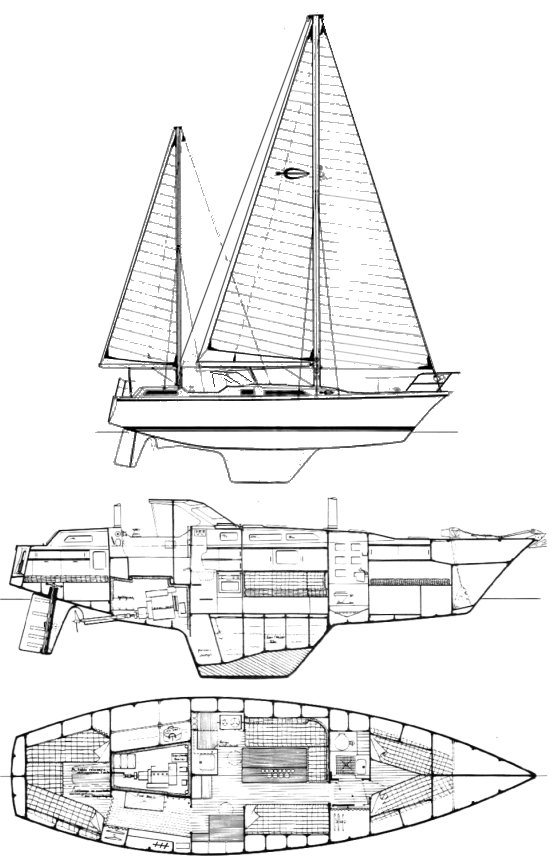

Kirk, Mango, Maramu, and Super Maramu are the best-known models from the Amel shipyard, and you can find plenty of information about these boats online. However, when searching for the Amel Sharki, information is not as abundant. Nevertheless, this boat was also built following the shipyard’s very high standards and is very interesting because with its 11.96 meters in length and a beam of 3.56 meters, the Sharki is a ketch-rigged sailboat that is well-suited for those who want to undertake sailing at any latitude solo or as a couple.

Amel Sharki, What a Discovery

It’s during the search for my ideal boat that I coincidentally meet Giorgio Ardrizzi via social network, author of the splendid book “Patagonia and Tierra del Fuego Nautical Guide“. Talking about my interest in buying a boat and one day returning to sail in Patagonia, he immediately becomes passionate about my story and starts giving me advice. After seeing and rejecting some boats in Tuscany, he tells me to take a look at the Amel Sharki, a boat he bought second-hand in 1989 and with which he has been sailing for 25 years now (16 of which spent in Patagonia). He also advises me to look at the Amel Santorin, which is slightly larger. I start researching, realizing that this boat has several truly interesting details and features, has an accessible cost, and is ideal for the type of sailing I would like to undertake.

Performance and Maneuverability

In port, the Sharki maneuvers well, and on more recent models, a bow thruster has also been installed, which simplifies maneuvering even further, especially when it’s windy. The propeller is right-handed, so the boat turns well clockwise in maneuvers, and with some throttle bursts and the rudder fully to starboard, it can easily turn 360 degrees. Its draft is 1.85 meters, allowing easy access to many places.

The steering wheel is always very smooth, even in strong winds, as long as the sails are properly reefed. Its limitations are upwind sailing with light wind and waves against, where it lacks a bit of power. If there are no waves, it points well and speed is good even with light wind. When the wind increases, the boat sails with great comfort and never gives the impression of straining.

Reefing the mainsail when the wind increases above 15 knots brings more comfort on board and maintains ease of maneuver without losing speed. The ketch rig moves the center of effort lower compared to a sloop, thus increasing the stability of the boat under gusts. Moreover, the individual sails have a smaller surface area, making them easier to handle. It’s a good boat for long stretches, maintaining good averages without tiring the crew.

On long stretches, Giorgio normally manages to maintain an average of 140 miles per day. He has even managed to cover 170/180 miles in a day. Normally, the shipyard provides two spinnaker poles with the Amel system that allow easy rigging of 2 genoas butterfly style.

What would be advisable to set up is a small bowsprit to mount a gennaker for downwind sailing with winds under 15 knots.

Amel boats have never had spinnakers, because it’s a demanding sail that, in the shipyard’s philosophy, they don’t consider suitable for the type of crew that usually buys that type of boat. For this reason, they designed their special genoa poles.

Solo Sailing or with Reduced Crew

My project involves starting alone, so there’s a need for maneuvers, tacking, or reefing to be operations that can be carried out simply, without too much effort, and above all, safely.

Amel sailboats are born precisely with this objective and have therefore been equipped with an electric furling system, lines led back to the cockpit, autopilot (in older models there was the Neco, later replaced with Raymarine 6000), and in the latest Sharki models, electric in-mast furling, bow thruster, and windlass control in the cockpit were also installed. The furling mainsail arrived concurrently with the start of Amel mast production, born from the acquisition of the Swiss company Nirvana, which produced high-quality masts.

The Engine Room

A characteristic of Amel designs is the engine room accessible from the central cockpit through a hatch. All the boat’s main systems are located in this area (batteries, generator, water heater, …). One of the best points of this design is that inside the boat you never have a diesel smell because these components are completely isolated. You can work in the engine room, take a break, and close the hatch without having dirty parts and tools scattered around the boat. It’s also important to keep in mind: most Amel Sharkis on the used market still have the original engine with 5000 or more hours, so it’s foreseeable that sooner or later it will be necessary to replace the engine. This can be done very easily thanks to the easy access, without having to resort to a contortionist mechanic. An engine that fits perfectly is the Yanmar 54 HP.

The Amel Sharkis were initially supplied with a Perkins 4108, then in the last years of production, a Perkins Prima M50 was installed. I’ve read conflicting opinions about the Prima M50, some say it’s a good engine, others say it has grounding problems and especially that spare parts are very expensive. The boat I went to see had a Prima M50, and indeed the owner had laid a cable from the engine to the water, like a ground. Maybe there’s some truth to it. A peculiarity of the Sharki is that it’s equipped with 3 alternators: two traditional ones to charge the engine and service batteries, while a third is installed on the propeller shaft, which can provide 15 A when sailing at 7 knots under sail.

Safety

In the Amel Sharki, there’s an internal watertight bulkhead that separates the bathroom and forward cabin from the rest of the boat. The forward bilge is connected to the midship bilge through a lockable valve. A notable safety feature. The anchor locker is also watertight. In case of hitting something at sea, the chances of survival are thus significantly increased.

Most production boats don’t offer watertight compartmentalization.

“One hand for the boat and one hand for yourself“, this is what I was told from the first times I set foot on a boat. An unexpected wave or a gust that suddenly heels the boat, and in an instant, you can find yourself against a table or an unpadded corner. The worst thing is ruining your day with a broken rib…

If you move around on an Amel, there’s always a handhold to grab, and even in rough seas, you can move along the entire boat without fear of being thrown to the other side.

Another peculiarity, the berths in the cabins have lee cloths as standard equipment, while in the saloon there’s a backrest that can be moved and used as a lee cloth system.

The Peculiarities of Amel Boats

Amel also installs a chain washer, a computer for electrical consumption, a gangway/swimming ladder, a mechanical water level indicator, the much-discussed synthetic teak, etc. Another peculiarity is the drainage of water from sinks and shower: the water is drained into a grey water tank positioned in the keel. This way there are no pumps that keep running (I’m thinking especially when someone goes to the bathroom at night), but you can decide to empty the tank when needed. The hull and deck were made by stratification using their own oval section fabric, which allowed thinner structures to be made using a proportion of 60% fabric and 40% resin, while normally the proportion is reversed. This allows obtaining thinner thicknesses with equal strength and therefore lighter.

Heating

It seems that the Eberspacher heaters installed in the early 80s have asbestos inside. From research done online, particular reference is made to units installed on ’84 Sharkis, where some owners have been refused maintenance or repair of the heater due to the presence of asbestos. This was also confirmed by Eberspacher itself during a meeting at the Paris boat show by an owner.

I asked for information online and it seems that it’s present in the form of pressed wool, very dangerous because if it’s touched and manipulated it easily creates particles. This asbestos is found inside the combustion chamber to insulate the burner and as long as it’s not opened there’s no danger. To be clear, it’s not in contact with the heated air circulating in the boat. It should be noted that these old heaters consume a lot of electricity and fuel, so ideally it’s advisable to replace the unit with something more recent. If instead you want to keep it at all costs and want to remove the asbestos, it’s possible to take the heating unit to a company that disposes of asbestos and they, properly equipped, open it, remove the asbestos and vacuum the particles, returning the open unit. At this point, you can insulate with 1200 degree ceramic rock wool. But honestly, I don’t know if it’s worth it…

The Galley

The refrigerator that was installed was one of those normal household ones, powered at 230V. In addition, they put a Frigoboat. The ’89 Sharki I viewed had a 12V refrigerator: I couldn’t find information to understand if over the years Amel replaced the 230V models with 12V ones or if the previous owner had replaced it on that boat. The galley area, compared to the Maramu which has a U-shaped galley, remains open towards the saloon.

Technical Characteristics of the Amel Sharki

Shipyard: Amel, France

Designer: Henri Amel/J. Carteau

Production period: 1979 – 1989

Material: GRP

Length overall: 11.96 m

Maximum beam: 3.56 m

Draft: 1.85 m

Displacement: 7,802 kg

Ballast: 3,202 kg

Sail area: 74.97 sq m

Height above DWL: 14.95 m

Engine: Perkins 4108 (48HP) and Perkins Prima M 50 (50HP)

Water tank: 757 L

Fuel tank: 341 L

Cabins: 2

Bathrooms: 1 forward

Mr. Amel

Henri Amel, born Henri Tonel on April 16, 1913, became passionate about sailing at a young age.

At the end of his adolescence, he undertook his first voyages aboard small sailboats.

It was in his car body shop in Paris that he began building boats and, after being mobilized in the war, he resumed his activity in Lyon.

Injured in one eye during the war, after a few years he lost his sight completely. This event didn’t stop him and he didn’t abandon his dream of building sturdy, comfortable sailboats that were simple to maneuver even solo. He then began designing boats and having them built by some shipyards, but unfortunately it didn’t work: one shipyard went bankrupt, another couldn’t follow Amel’s requirements, and another couldn’t build the boats despite numerous orders.

He couldn’t digest the last failure and therefore decided to take over the ARPIN company (Ateliers Rochelais de Polyester Industriel et Naval) founding AMEL in La Rochelle.

A great supporter of fiberglass, he would be a pioneer in this field and from this shipyard would come the Super Mistral, the Pampero, the Euros (1967), the Garbi (1970), the Meltem (1973) up to the Sharki, Maramu, Mango and so on. Henri Amel is an extreme perfectionist, a quality he passes on to his team, obtaining a production of the highest quality.

In 1980, Henri Amel donated the shipyard’s shares to his employees, symbolically keeping only one for himself.

The website: www.amel.fr

Amel owners group: Amel Yacht Owner

Last update: